Turning Copper into a Superbug Bacteria Killer

Although hospitals are supposed to be a place of treatment and recovery, many infections actually begin in hospitals, termed hospital-acquired infections. The Centers for Disease Control and Prevention estimates that at any moment, one in thirty-one hospital patients has at least one hospital-acquired infection, caused by microbes such as the superbug Methicillin-resistant Staphylococcus aureus (MRSA). This translates to an average of 1.7 million infections and 99,000 deaths per year. The annual financial burden in the United States is estimated to be as high as $45 billion. Because of these statistics, hospitals are motivated to integrate effective prevention strategies, and researchers have stepped up to develop technology to attack these infectious microbes.

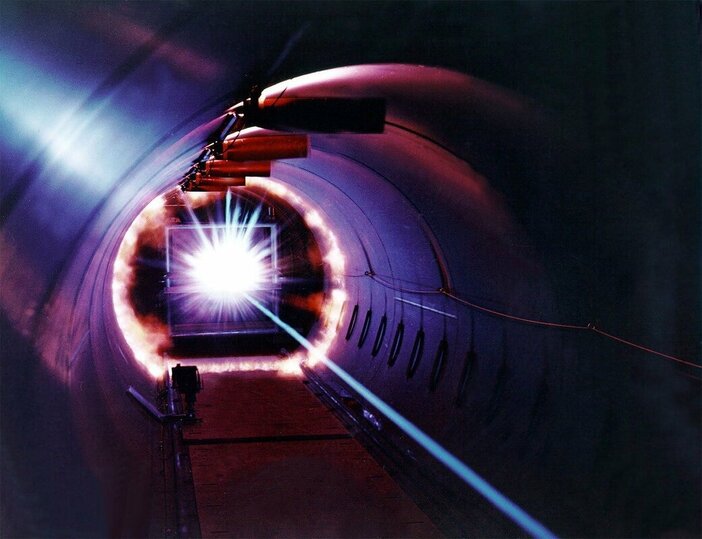

Recently, researchers at Purdue University have responded to this need with the introduction of a new laser-treatment method that can transform copper surfaces into bacteria killers. Copper has long been known to exhibit antibacterial properties, with its first medical use dating back to the times of ancient Egypt. Copper does this by destroying the structure and genetic material of bacteria. This mechanism of attack makes it less susceptible to bacterial resistance, which has become a heightened health concern in recent years. The new laser treatment enhances copper’s antibacterial properties by modifying the texture and composition on the surface without compromising the overall quality of the copper. The textured surface increases its surface area and thus allows for more opportunities for bacteria to come into contact with the metal.

Recently, researchers at Purdue University have responded to this need with the introduction of a new laser-treatment method that can transform copper surfaces into bacteria killers. Copper has long been known to exhibit antibacterial properties, with its first medical use dating back to the times of ancient Egypt. Copper does this by destroying the structure and genetic material of bacteria. This mechanism of attack makes it less susceptible to bacterial resistance, which has become a heightened health concern in recent years. The new laser treatment enhances copper’s antibacterial properties by modifying the texture and composition on the surface without compromising the overall quality of the copper. The textured surface increases its surface area and thus allows for more opportunities for bacteria to come into contact with the metal.

Image Source: Wikilmages

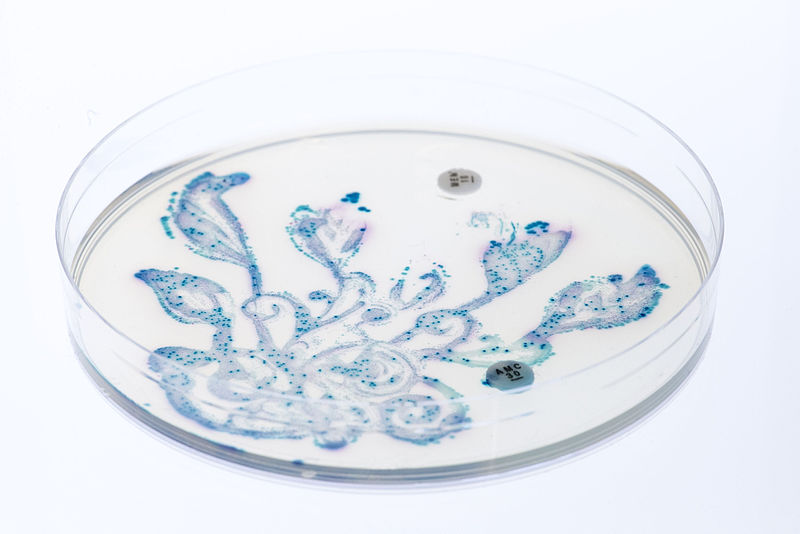

To demonstrate the efficacy of this laser method, the researchers covered treated and untreated copper samples with four different strains of bacteria known to be common causes of infections, including MRSA. While normal copper killed only two of the bacterial strains, the laser-treated copper was able to eradicate all of the different types of bacteria tested. Moreover, the laser-treated copper killed each bacteria at a significantly faster rate. Finally, the researchers exposed the textured copper to two types of mammalian cells and found that they still had high survival rates. As a result, this implied that copper is selective to killing only bacterial cells and not human cells. Therefore, this is a technique that can and should be used in the clinical settings.

Importantly, this method of killing bacteria is distinct from other methods currently being researched because of its practicality. It is a fast and powerful one-step process that can be completed without the need for excessive, expensive equipment. Because of its simplicity and cost-effectiveness, this process proves to be industrially relevant. Researchers believe this laser-treatment method can immediately be applied to highly touched surfaces in hospitals, such as handrails and doorknobs, and can be easily incorporated into medical device manufacturing processes. The possible uses of this new technology do not stop there!

Further research has already begun to test this treatment on a variety of other metals used for clinical tasks. The researchers are hopeful that this technology can be used to reduce the risk of bacterial growth and subsequent biofilm formation on medical implants, which currently account for around 45% of hospital-acquired infections. With this advancement, researchers are taking a pivotal step forward toward preventing high rates of hospital-acquired infections.

Importantly, this method of killing bacteria is distinct from other methods currently being researched because of its practicality. It is a fast and powerful one-step process that can be completed without the need for excessive, expensive equipment. Because of its simplicity and cost-effectiveness, this process proves to be industrially relevant. Researchers believe this laser-treatment method can immediately be applied to highly touched surfaces in hospitals, such as handrails and doorknobs, and can be easily incorporated into medical device manufacturing processes. The possible uses of this new technology do not stop there!

Further research has already begun to test this treatment on a variety of other metals used for clinical tasks. The researchers are hopeful that this technology can be used to reduce the risk of bacterial growth and subsequent biofilm formation on medical implants, which currently account for around 45% of hospital-acquired infections. With this advancement, researchers are taking a pivotal step forward toward preventing high rates of hospital-acquired infections.

Featured Image Source: Ra Dragon

RELATED ARTICLES

|

Vertical Divider

|

Vertical Divider

|

Vertical Divider

|